makerdad

makerdad

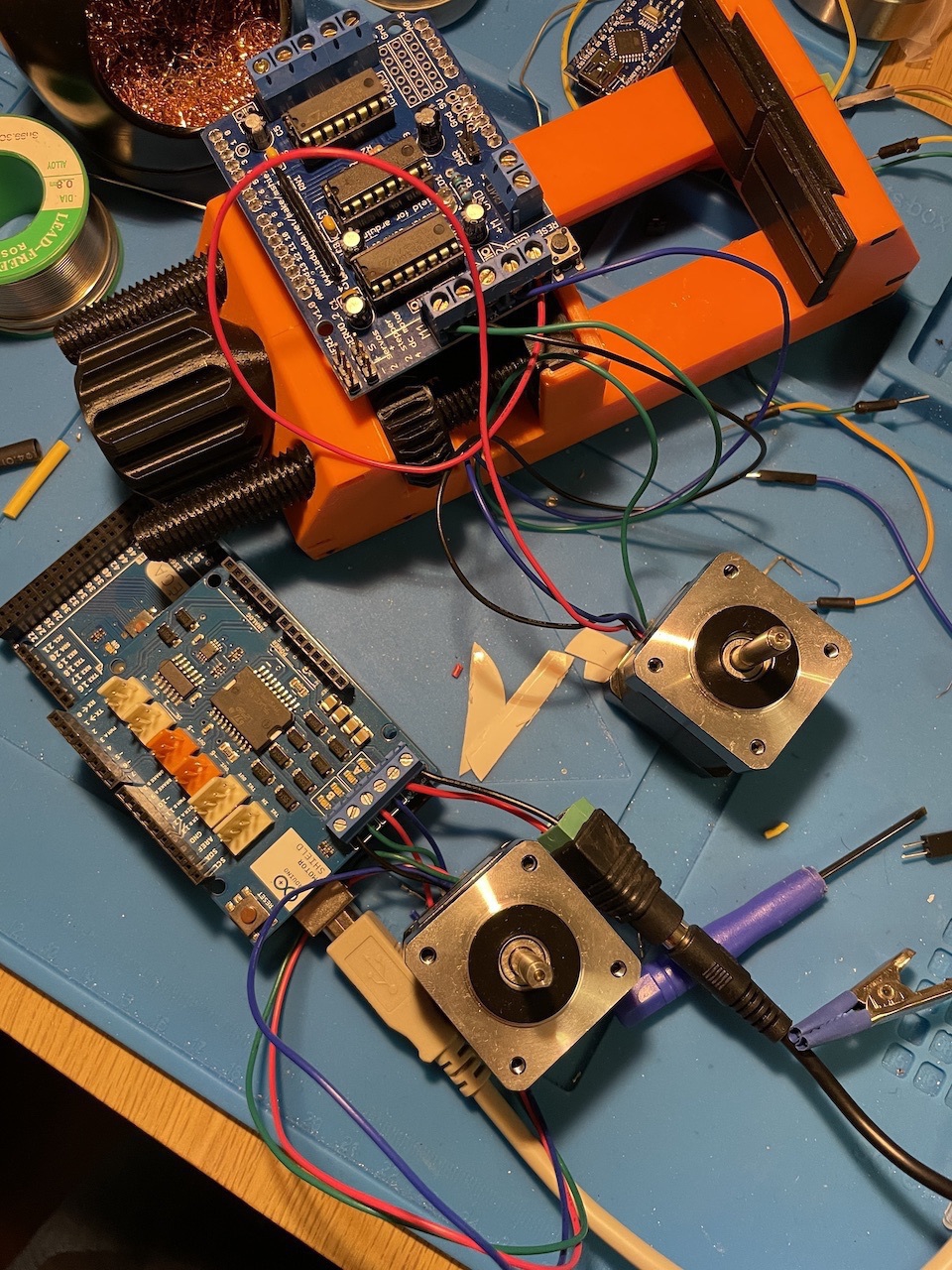

Stepper Motor Hell

I got the stepper motor working tonight. This was significantly harder than I expected. I had several motor driver boards lying around, and thought I would make my job easier and use an Arduino Motor Shield. As it turns out, running steppers with it is not that straightforward. I tried several libraries, everything from the standard Stepper library to the AccelStepper, which is supposed to be state of the art.

There are a few things that threw me off, in no particular order:

The NEMA-14 I am using is a 4-cable bipolar motor. I tried to initialize the libraries with pins for all 4 coil cables, and this doesn’t work. Apparently what you are supposed to do is to use the 2-cable setup, but then set the PWM pins to HIGH in setup:

Stepper stepper(stepsPerRevolution, DIR_A, DIR_B);

void setup() {

pinMode(PWM_A, OUTPUT);

pinMode(PWM_B, OUTPUT);

pinMode(BRAKE_A, OUTPUT);

pinMode(BRAKE_B, OUTPUT);

digitalWrite(PWM_A, HIGH);

digitalWrite(PWM_B, HIGH);

digitalWrite(BRAKE_A, LOW);

digitalWrite(BRAKE_B, LOW);

stepper.setSpeed(400);

}

Same idea applies to AccelStepper. Brake pins are needed only because of the Arduino Motor Shield’s setup.

I eventually got the motor to run with the AccelStepper library, but it was very unreliable. Even though I wanted it to run at a constant speed, motor would continuously accelerate or decelerate, and eventually would stall. In addition, I noticed that trying to use Serial during operation was a big problem with AccelStepper. It would change the way the motor was running.

I also ran some tests on the Adafruit Motor Shield rev1 I had from many years ago. Again, I could get the motor to run, but it was unreliable. In addition the board started smelling funny and I noticed that the L293D H-bridge driver getting very hot.

Finally, I decided to get back to basics. I hooked the Arduino Motor Shield up, loaded up the Stepper library again and wrote the simplest stepper program:

void setup() {

stepper.setSpeed(400);

}

void loop() {

stepper.step(1);

}

After fiddling with the speed a bit, this actually worked! I elaborated on it a bit more to confirm the RPM:

void loop() {

stepper.step(1);

currentStep += 1;

if (millis() - lastCheckTime >= 60000) {

Serial.print("RPM: ");

Serial.println(currentStep / stepsPerRevolution);

currentStep = 0;

lastCheckTime = millis();

}

}

And sure enough, I got an RPM reading of 398. It’s good enough for the LIDAR, and I can safely print things out to the Serial.

Next step will be designing the pulley system. I got the 42mm bearing and the timing belt today. It’s going to be fun to hook up the whole mechanism.